Programs

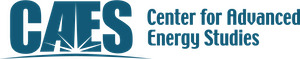

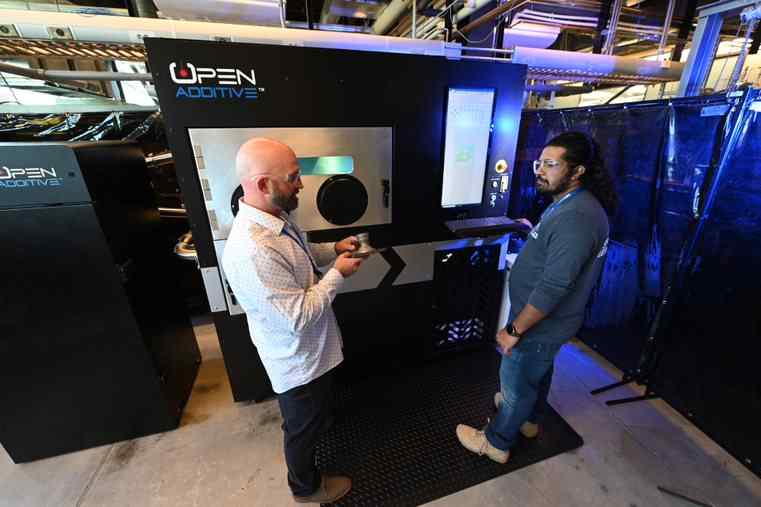

CAES programs create a collaborative environment between the universities and Idaho National Laboratory that empowers students, researchers, faculty and industry to accelerate energy solutions.

Research

CAES research harnesses the power of collaboration between the universities and Idaho National Laboratory to address complex energy challenges and accelerate energy solutions.